Page 11 - January1960

P. 11

January, 1960 NATIONAL BUTTON BULLETIN

The initials "F.8." are the signature of the Bapterosses film. "Brevetes

S.D.G.D." is the patent notice. The large figures are probably stock numbers.

The material of all gaiter buttons resembles the old ironstone china, so one

may assume they were made from ingredients somewhat similar. The manufac-

turing technique was the revolutionary one that made calico buttons possible-

that is, the compression of dry powder.

CONSTRUCTION

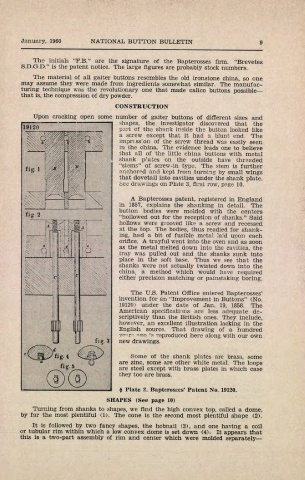

upon cracking open some number of gaiter buttons of different sizes and

shapes, the investigator discovered that the

p,r:.'t of the shank inside the button looked like

a screw excepf that it had a blunt end. The

imprcss.on of the screw thread was easily seen

in the china. The evidence leads one to believe

that all of the little china buttons wlth metal

shank p'ates on the outside have threa,ded

"stem:" of scretv-in type. The stern is further

anchorad and kept frorn turni:rg by small wings

that dovetail into cavities under the shank plate.

3e.: dlirwirrgs on Plate 3, fit'sr row, page 10.

A Bapterosses patent, registered in England

in 1857, exolains the shanking in detail. The

button bodies $r'ere molded with the centers

"hollowed out for the reception of shanks." Said

hollows were glooved like a scretv and recessed

at the top. The bodies, thus readied for shank-

ing, had a bit of fusible metal lajd upon each

ofifice. A trayful went into the oven and as soon

as the metal melted down into the car,iLles, the

tray was pulled out and the shanks sunk into

place in the soft base. Thus we see that the

shanks were not actually twisted dorvn into the

china, a method which would have required

either precision matching or painstaking boring.

The U.S. Patent Office entered Baoterosses'

invention fol an "Imp|ovement in Buttons" tNo.

19120) undel the date of Jan. 19, 1859. The

American specificati.ns are less adequate de-

scripLively than the British ones. They include,

horvever, an excellent illustration lacking in the

English source. That drawing of a hundred

r,rp'r' .oo 's: reproduced here along with our own

new dratffings.

Some of the shank plates ale brass, some

are zinc, some are other vr'hite metal. The loops

are steel except with brass plates in which case

they too are brass.

t Plate 2. Bapterosses'Patent No. 19120.

SHAPES (See page l0)

Turning from shanks to shapes, we find the high convex top, called a dome,

by far the most plentiful (1). The cone is the second most plentiful shape (2).

It is followed by two fancy shapes, the hobnail (3), and one having a coil

or tubular rim within which a low convex dome is set down (4)' rt appe;rs that

this is a two-part assembly of rim and center which were molded separately-