Page 18 - May2008

P. 18

May 2008 THE NATIONAL BUTTOn BULLETIN 71

DECORATIVE FINISH (OF)

Raw/unfinished leather has no topical pigment applied. It may have a minimal

protective resin coating. Hides are immersed in organic non-protective aniline dye

which absorbs into the leather and accentuates the natural skin patterns. To test

your button to determine if it is unfinished (dye only) you can conduct a simple

water drop test. Unfinished leather will result in the test area absorbing the water

drop and darkening. Unfinished leather will also have a "buttery" feel. Finished

leather resists staining from water and oil-based agents. A water drop on finished

leather will stay above the surface and will not soak in or darken the leather.

• Paint Usually acrylic, this most common coloring remains on the surface and

is not absorbed into the body (like dye). These usually have an additional clear

urethane coating for added durability. The clear coat creates a film that bonds

to the surface for wear, stain and fade resistance. Clear coat resin sealers have a

reflectivity range from high gloss to matte and dull depending on how much

dulling agent is added .

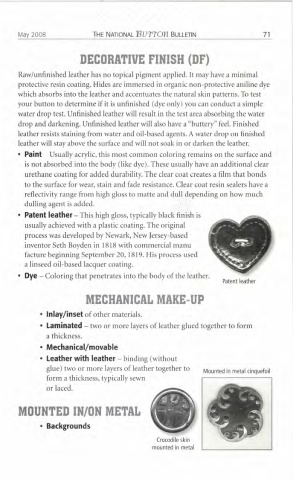

• Patent leather - This high gloss, typically black finish is

usually achieved with a plastic coating. The original

process was developed by Newark, New Jersey-based

inventor Seth Boyden in 1818 with commercial manu

facture beginning September 20,1819. His process used

a linseed oil-based lacquer coating.

• Dye - Coloring that penetrates into the body of the leather.

Patent leather

MECHANICAL MAKE-UP

• Inlay/inset of other materials.

• Laminated - two or more layers of leather glued together to form

a thickness.

• Mechanical/movable

• Leather with leather - binding (without

gl ue) two or more layers of leather together to

Mounted in metal cinquefoil

form a thickness, typically sewn

or laced.

MOUNTED INION METAL

• Backgrounds

mounted in metal